QUALITY

Engineered Excellence,

From Start to Finish.

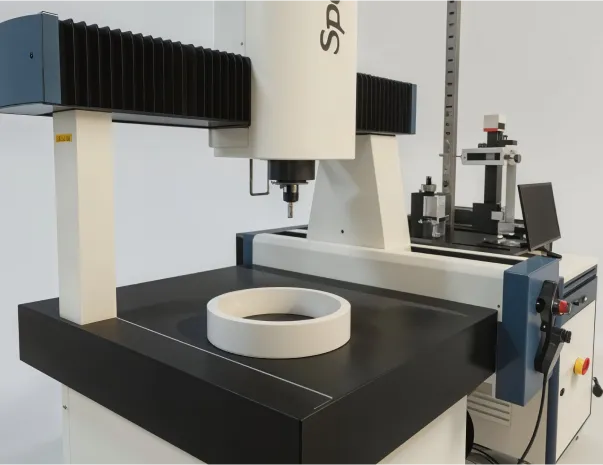

At CeramForge, quality is not a checkpoint—it's a mindset. Our commitment to delivering high-performance engineered ceramic components begins with stringent raw material evaluation and continues through every stage of the manufacturing process, culminating in rigorous final inspections.